| W200: | Sales points of WT200 series in comparison to Yamato VE |

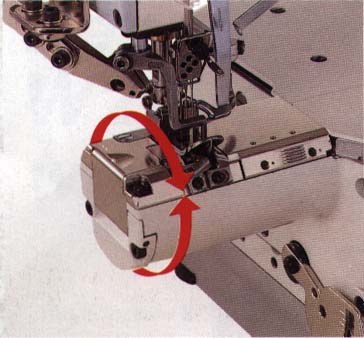

In the last PPE-news we introduced the W(T)200 series and it 's advantages in applications, especially for hemming with small circumferences and coverseaming cuff seams, previously sewn on with an overlock machine. The increase in productivity on coverseaming cuff seams is tremendous, up to 3 x in comparison to the old method, which required 3 - 4 stops for handling.

Now the operator sews without a stop.

Further information and advantages of W(T)200 - series:

| ü | Stitch condensed device, MS-100 is useable with the correct motor. |

| ü | Independent driven top feed i.e. the movement remains the same if the stitch length is changed. |

| ü | The top feed dog orbit is adjustable to advanced or delayed timing. |

| ü | Needle bar stroke is 31,0 mm of W200 and 33,4 mm of WT200 (thicker material) |

| ü | Gauge parts: needle plate, rear and front needle guard, main and diff. feed dog are new designed and the presser foot, the top feed dog, looper and spreader are of W(T)600-series |

| ü | The UT-device is the same as W(T)600-series. |

| ü | The auxiliary front cover (250425) is included in the accessories. |

We show you below the comparison chart, datas provided from Pegasus, of W(T)200 and Yamato VE-series:

Sales Points of W (T) 264 versusYamato VE-seriesFeatures |

PEGASUS |

YAMATO |

| intermittent system on differential adjustment ( quick adjustment ) | yes |

no |

| top cover thread | yes |

yes |

| differential feed adjustment | lever, easy |

screw driver, not easy |

| condensed stitch device | MS-100 |

also |

| max. speed | 5000 sti./min. |

4500 sti./min. |

| arm circumference | 177 mm |

180 mm |

| distance of needle drop point to casing |

65 mm |

71 mm |

| left side of arm to centre of needle |

37 mm |

45 mm |

| differential ratio | 1:0,8 - 1:1,4 |

1:0,8 - 1:1,2 |

| max. differential feed | 1:0,8 - 1,8 |

1:1.0 - 1,4 |

| max. movement of diff. feed dog | 5,88 mm |

5,04 mm |

| stitch length | 0,9 - 4,2 mm |

1,4 - 4,2 mm |

| needle guard | moveable, fixed to looper |

separate moving needle guard, better |