| W 200: | New small free arm interlock-machine with differential bottom feed mechanism |

| WT 200: | New small free arm interlock-machine with differential top and bottom feed mechanism |

|

We have

introduced this new machine model with the very small cylinderarm as W200 with

differential bottom feed and as WT200 with variable top feed and differential bottom feed.

We will inform you about some more details and advantages of this new W(T) 200-series and

the available subclasses. The circumference of the small cylinder arm is only 170 mm. |

1. Available subclasses:

1.1 WT264-08BBx248/M/UT450

The WT664 in subclass -08 is for hemming bottoms and sleeves of small size articles of children’s and baby wear like T-Shirts, Polo - Shirts and underwear. It offers a great advantage in handling, increases the productivity and it is possible to sew the hem without any stop. Other available needle distances: x232, x 240, x 356, x 364.

Application and advantages of the differential top feed for hemming operations:

The differential top feed offers a great advantage when sewing fabrics with high elasticity or sewing a wide hem, where no roping hem will occur. Ribbed fabric can be easily sewn with ribs from top and bottom matching and the ribs between the needles will be straight and not on a slant like on a machine without top feed mechanism. No shorter stitches on cross seams and easy climbing over cross seams.

no shortened stitcheson cross seams

and no skipped

no shortened stitcheson cross seams

and no skipped

no roping hem, perfect flat

no roping hem, perfect flat

In each above named case a dramatic quality improvement can be easily achieved and no pressing is required because the hem is perfectly flat. The flat finish gives an additional saving of labour, generating steam and saving of wear and tear of steaming equipment.

1.2 WT264-03FBx356/M/UT450:

The WT264 in subclass -03 is for coverstitching overlock seams, flattening out the previously sewn overlock seam, to achieve a nice and flat finished seam increasing the comfort of wearing this garment: x 240, x 248, x 256, x 264, x 356 und x 364.

Application and advantages of the differential top feed for coverstitching ( flattening out ) overlock seams:

The differential top feed gives a great advantage when sewing fabrics with higher elasticity or flattening out the sleeve seam, where on the front and back panel of a garment the courses are opposite to the courses of the sleeve. Even with these different directions of courses, i. e. different elasticity, it is possible to obtain a flat seam without any seam pucker. A quality improvement is easily achieved. The top feed additionally provides good transport of the fabric over cross seams without shortened stitches

even and flat performed

even and flat performed

(Please, see also pictures on left side).

Again it is possible to reduce steaming or pressing dramatically. This gives an additional saving of labour, generating steam and saving of wear and tear of steaming equipment.

1.3 WT264-01CBx356/M/UT450

This subclass is for plain seaming operations, like joining two pieces of fabric overlapped. The machine can be equipped with different guides for various applications.

Other available needle distances: x 232, x 240, x 248, x 256, x 264, x 356 and x 364.

|

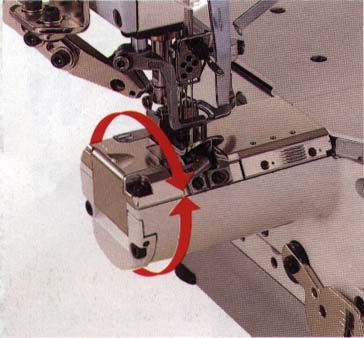

Showing the location of the differential top feed adjustment, located right in front of the operator at the machine arm. Easy accessible, easy and accurate to adjust with micro-fine adjustment |

2.1 W2664-01CBx3356/M/UT452

The W264 in subclass -01 is used for the same application like WT264-01 but in conjunction with less critical material, i. e. less stretch and elastic material or none ribbed fabric.

Other available needle distances: x 232, x 240, x 248, x 256, x 264, x 356 and x 364.

2.2 W264-03FBx356/M/UT452

For coverstitching ( flattening out ) overlock seams to improve the quality of the article and to increase the comfort of wear. Used for less critical fabric, thinner fabric with less difficult cross seams. Available in the same needle distances like WT264-03.

2.3 W264-08BBx248/M/UT452

The W664 in subclass -08 is for hemming bottoms and sleeves of small size articles of children’s and baby wear like T-Shirts, Polo- Shirts and underwear. It offers a great advantage in handling, increases the productivity and it is possible to sew the hem without any stop. The same needle distances like WT264-08 are available.

3.0 Different versions of the same subclass as WT264 and

W264:

3.1 In subclass -03 are 2 versions available.

Version -FB for coverstitching in the middle of the seam and flattening the seam. The needle plate has a throat for additional guiding and flattening of the fabric. The guide on the presser foot is fixed. This version is mainly used for medium heavy and heavy fabric. Version -GB for coverstitching in the middle or off the middle of the seam. The overlock seam is folded to one side. The needle plate is stepped to compensate for the different layers of fabric. On one side are three layers of fabric and on the other side is one layer only. The guide on the presser foot is adjustable. This version -GB is used for fine and fine to medium fabric, like single jersey.

3.2 In subclass -08 are 2 versions available

as well.

Version -AB is for standard size hem on fine to medium weight fabric. The feed dog pattern is small. The left side guide is fixed on the needle plate and the right side guide is adjustable. Version -BB is for wide size hem for medium weight or heavy weight fabric. The feed dog pattern is wide for more intensive transport of the fabric.

4.0 UT - Devices and MS - device

Different UT-devices are available for W264 or WT264, with or without top cover thread trimmer:

UT450 für die WT264-01, -03 und -08.

The UT-device is pneumatically operated and includes presser foot lifter and pneumatically

operated top cover thread trimmer.

UT452 für die W264-01, -03 und -08.

The UT-device is pneumatically operated and includes presser foot lifter and pneumatically

operated top cover thread trimmer.

UT326 für die W264-01, -03 und -08.

The UT-device is without top cover thread trimmer, is pneumatically operated and includes

presser foot lifter and pneumatically operated thread wiper.

UT327 für die Wt264-01, -03 und -08.

Same as UT326 but for WT264.

MS-100

The W(T)200 - series has the same stitch length mechanism like W(T)600 - series. This allows the application of the MS-100 device, the condensed stitch and anti fraying to prevent an opening of the seam end. The condensed stitches are made automatically in conjunction with the correct motor controll panel, capable of condensed stitch function.The MS-100 saves one operation. To secure the seam end and stop it from fraying during washing, tumble drying or normal wear, is to add a bartack in a seperate operation on a bartacking machine.

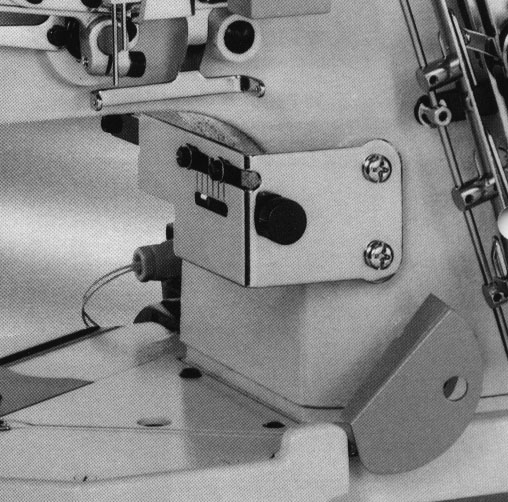

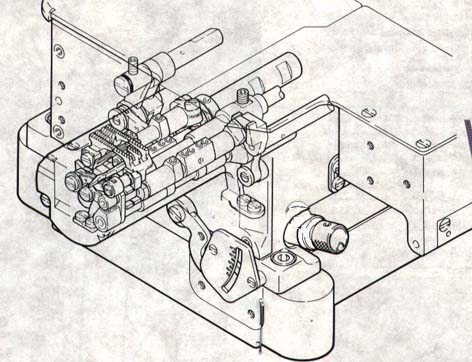

Showing the precision made mechanism in the 170 mm circumference small free arm

5.0 Some more technical details about the top feed mechanism of WT 264:

5.1 Maximum speed is 5500 stitches / min.,

provided that the stitchlength and the lift of the top feed are not more than 4 mm.

5.2 Maximum speed is 5000 stitches / min.,

if the maximum stitchlength is less than 4 mm and the lift of the top feed is more than 4 mm

5.3 maximum speed is 4500 stitches / min.,

if the maximum stitchlength is more than 4 mm and the lift of the top feed is more than 4 mm

We have the same conditions on WT500 and WT600 - series.

U. Rabe, PPE